Vacuum Heat Treatment

Features:

- Prevents surface reactions such as oxidation and decarburisation of work pieces

- Removes surface contaminants such as oxide films and residual traces of lubricants resulting from fabricating operations

- Retains surface finish

- Uniform heating

- Minimal distortion of treated work

- Wide range of Programmable heating and cooling rates

- Fully automatic processing

Heat Treatment Process:

- Through hardening for tool & die steels, machinery steels, plastic mould steels and high speed steels

- Annealing

- Stress relieving

- Tempering

- Age / precipitation hardening of non-ferrous materials

- Age / precipitation hardening of maraging steel

- Hardening of martensitic stainless steel

- Solution treatment

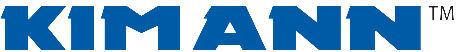

Gas Fired Furnace Heat Treatment

Features:

- Wide range of programmable heating and cooling rates

- Big heating chamber

- Quenching mediums include water and polymer

- Suitable for wide range of material grades

Heat Treatment Processes:

- Harden and temper

- Tempering

- Stress relieving

- Annealing

- Normalising

- Age / precipitation hardening of non-ferrous materials

Controlled Atmosphere Furnace

Features:

- Prevents surface reactions such as oxidation and decarburisation of work pieces

- Controlled atmosphere with carbon potential measurement

- Uniform heating

- Direct quenching with minimal exposure to atmosphere

- Wide range of programmable heating and cooling rates

- Automatic in-line of quench capability

Heat Treatment Process:

- Through hardening for tool & die steels, machinery steels

- Carburising

- Carbonitriding

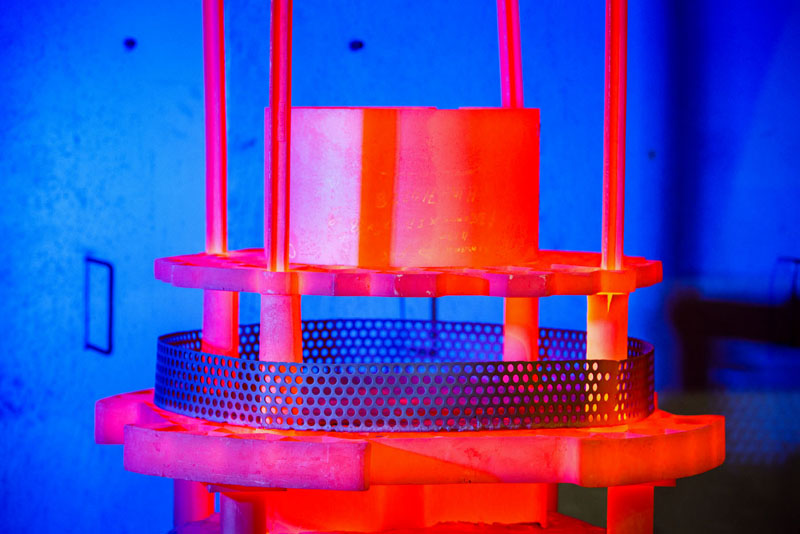

Plasma Nitriding

Features:

- Increase hardness and wear resistance of metal and alloys

- Low treatment temperature minimal distortion

- Capable of treating parts of stainless steel without predepassivation process

Heat Treatment Process:

- Plasma nitriding

- Plasma Nitro-carburising

Induction Hardening

Features:

- Increase surface hardness and wear resistance of metal and alloys

- The hardened layer resists cracking, bending, and fatigue under heavy loads

- Only the critical areas are hardened, while the core remain tough and ductile

- Rapid heating and cooling reduces warping compared to tradtional heat treatment

Heat Treatment Process:

- Surface hardening

- Induction Brazing