Our strip and wire products can be further processed via our in-house slitting machines, and traverse winding (TRW) and polycoil facilities.

Slitting

Precision slitting of both bare & pre-plated material, from master coil width of 430mm, to a minimum width of 4mm, with good quality control on width tolerance, camber, slitting burr, coil set etc.

Slitting of pre-plated material is carried out on a dedicated machine, to prevent scratches during slitting.

| Slitting Capabilities | ||

| Min. (mm) | Max. (mm) | |

| Thickness | 0.10 | 2.00 |

| Width | 4 | 400 |

| Coil Inner Diameter | 300 | 500 |

| Coil Outer Diameter | 600 | 1600 |

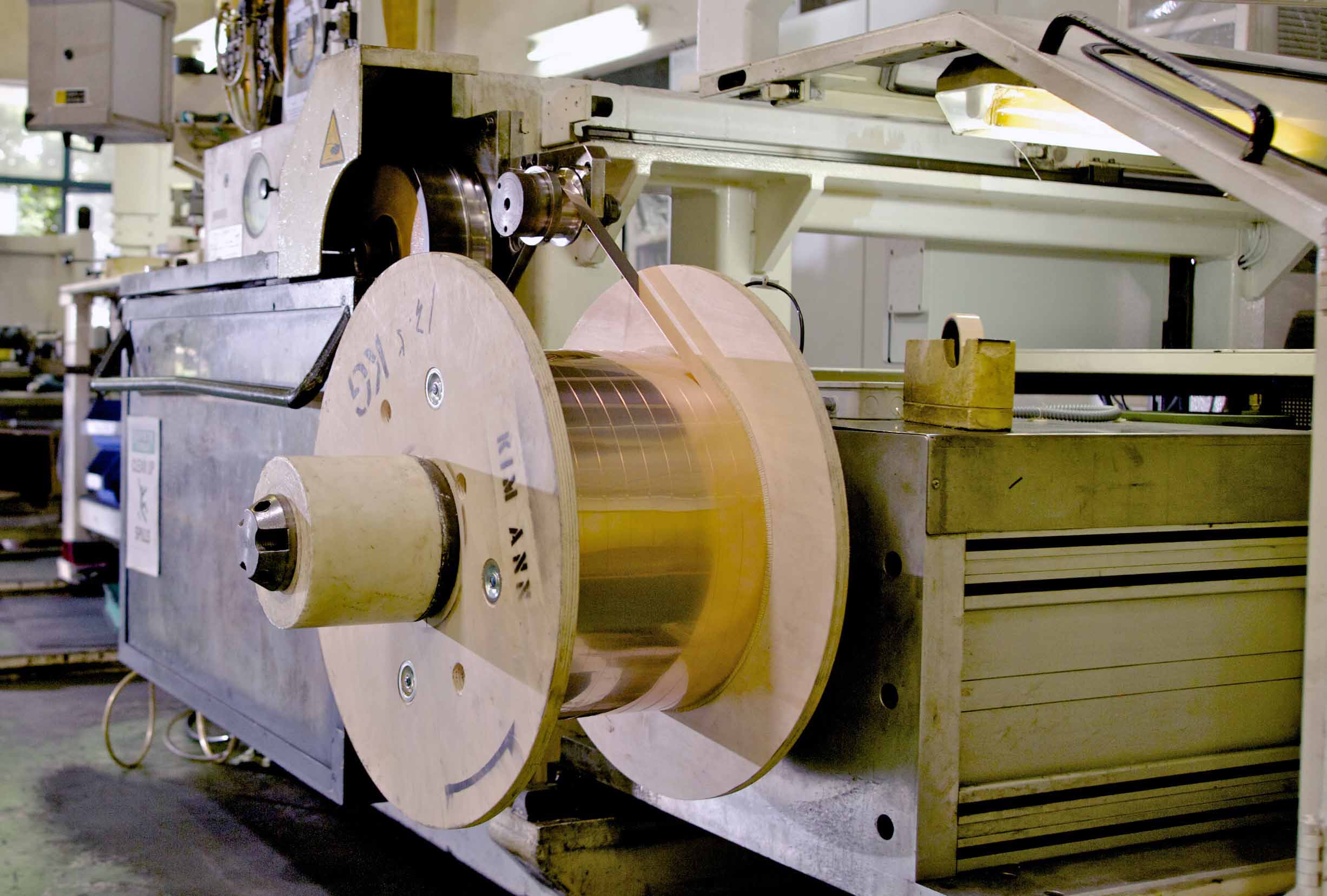

Traverse Winding

This process joins several coils together by welding and winding them onto a drum, having a material weight of 200 to 400 kg per drum. This is employed by many terminal & connector producers, and high volume run parts, to increase the production efficiency.

| Traverse Winding Capabilities | ||

| Min. (mm) | Max. (mm) | |

| Thickness | 0.15 | 0.8 |

| Width | 6 | 55 |

| Coil Inner Diameter | NA | NA |

| Coil Outer Diameter | – | 1200 |

| Drum Size | Type 9:250kgs / Type 8:450kgs | |

Polycoil

Unlike TRW, Polycoil is stacked vertically on a pallet, with more coils welded together, having a material weight of max 2000kg on a pallet.

Polycoil enables a even higher productivity, further reducing manpower and material yield lost.

| Polycoil Capabilities | ||

| Min. (mm) | Max. (mm) | |

| Thickness | 0.15 | 0.8 |

| Width | 10 | 80 |

| Coil Inner Diameter | 300 | 500 |

| Coil Outer Diameter | – | 1200 |

| Weight/Pallet | 2000kgs | |

Plating

Plated strips & wires with Tin (Sn) / Nickel (Ni) / Silver (Ag) & Gold (Au) plating are available.